Product

Product

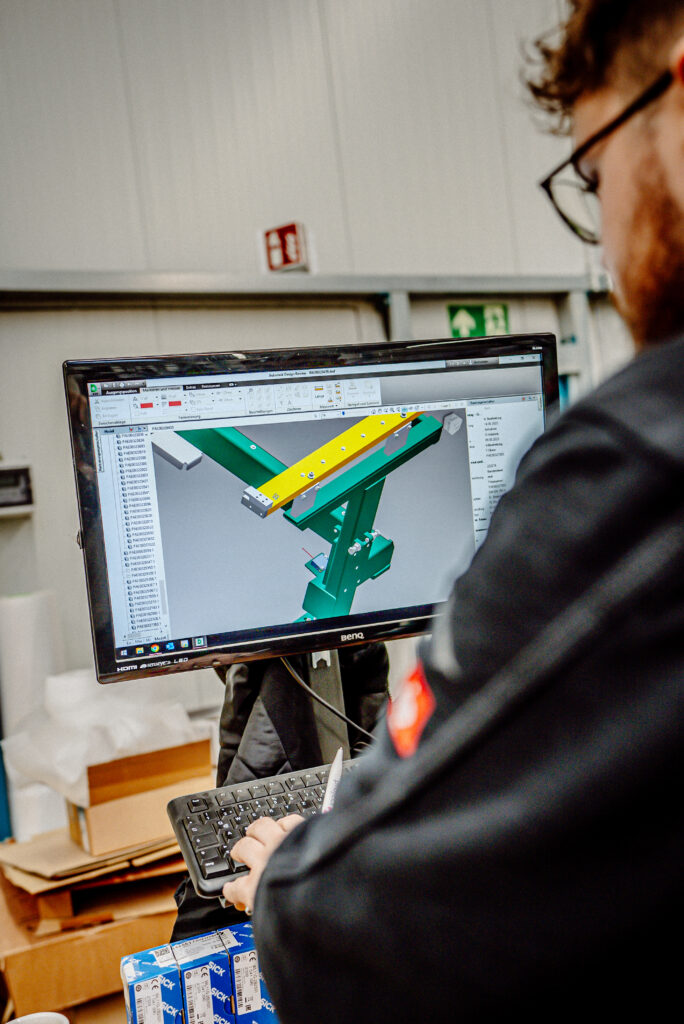

From palletizers to pick-and-place robots, labeling systems, cobots, banding machines, and stretch wrappers – project provides solutions that seamlessly integrate into existing production environments. The portfolio is complemented by specialized technologies such as the PROBAND V banding system, the PROGRIP carry-handle applicator, customizable gripper heads and high-performance conveyors.

Pick & Place

Product

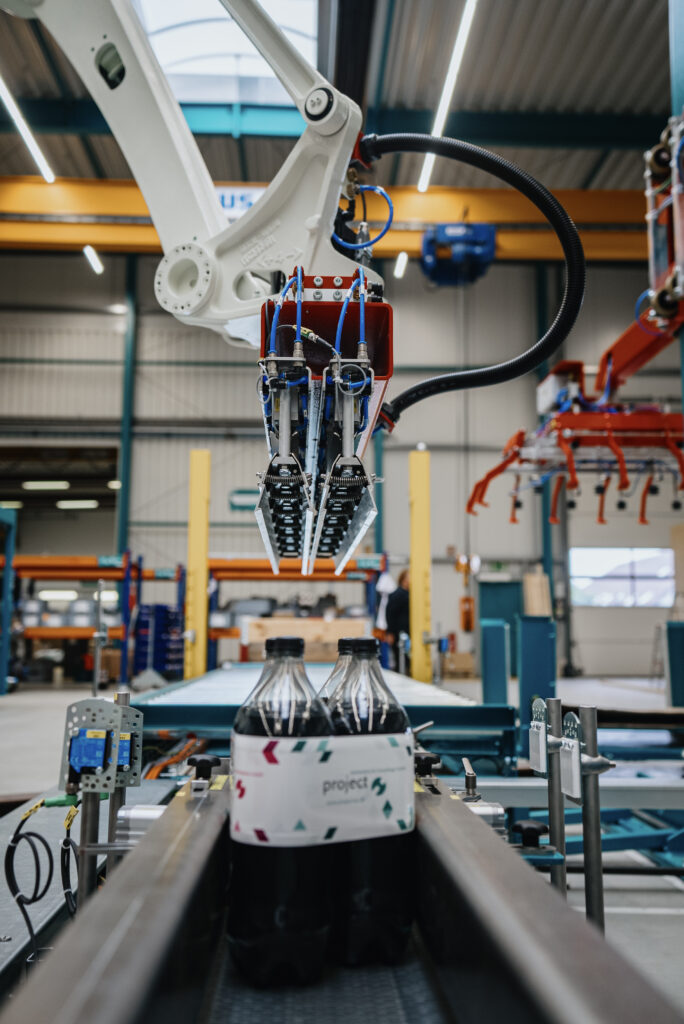

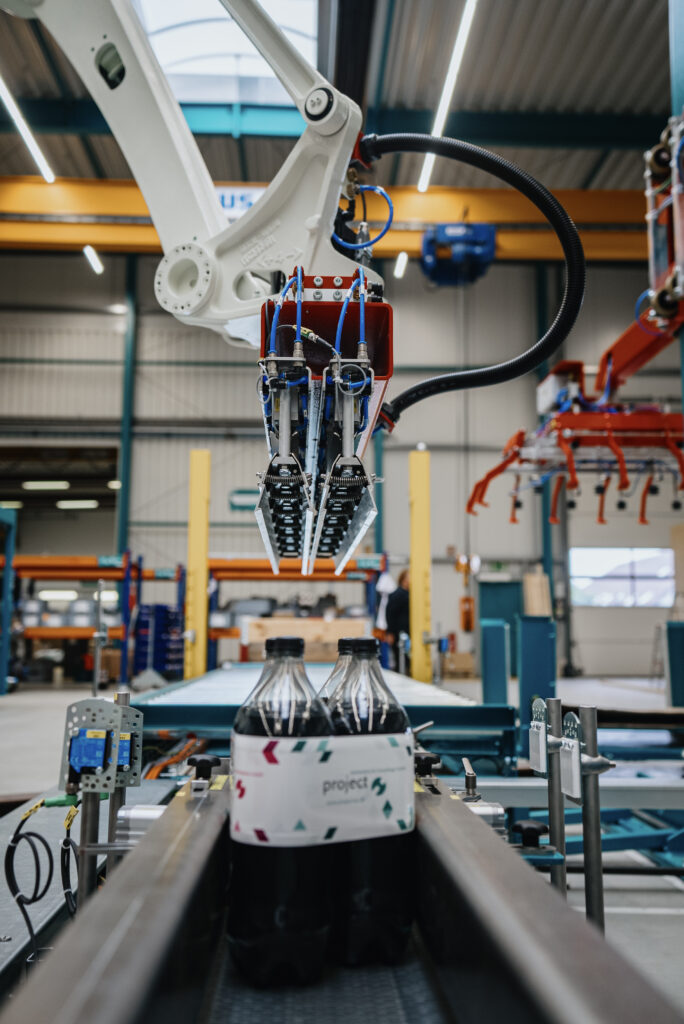

Packing Robot – PROPAC

Packing with PROPAC R

The PROPAC R110 automatically packs primary-packaged products into secondary packaging. Different containers are placed into cartons or crates – ready for immediate transport.

Packing with PROPAC C

This packaging machine is equipped with a cobot, which automatically places primary-packaged products into secondary packaging. Different containers are safely and reliably packed into cartons or crates. The special feature: A touch-sensitive cobot enables collaborative operation – without bulky protective fencing - and provides maximum flexibility in the production environment.

Packing with PROPAC L

The PROPAC L is the set-packer in the PROPAC series. This unit, such as the PROPAC L600, packs bottles into cartons. Thanks to its compact footprint, it can be easily integrated into even the tightest production spaces. The PROPAC L600 is highly versatile and can be quickly adapted to different products and formats.

Palletizing

Product

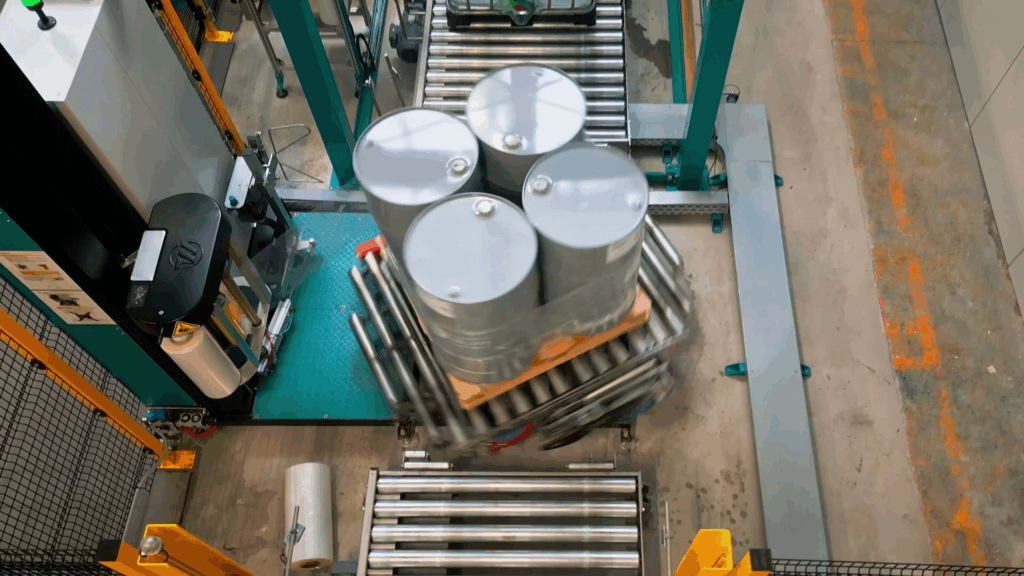

Palletizing with PROPAL

Robotic Palletizer – PROPAL R

The PROPAL R110 is a robotic system that automatically stacks cartons, bags, or similar pack units onto pallets. It meets the highest demands in terms of speed, safety, and automation. Thanks to its compact design, the system can be easily integrated into existing production lines and quickly adapted to individual requirements – powerful, flexible, and cost-efficient.

High-Performance Layer Palletizer – PROPAL R

The PROPAL R210 operates by forming and placing entire layers, enabling particularly high throughput in palletizing. As with all PROPAL systems, it offers speed, safety, and flexibility. Its compact layout allows for simple integration into existing lines. As a result, this palletizer provides a highly economical solution wherever speed and efficiency are critical factors.

Gantry Lift System – PROPAL P

The PROPAL P160 is a gantry-based lifting system designed for piece goods handling with an exceptionally large working range – making it ideal for use in large-scale, just-in-time warehouses. Unlike classic articulated robots, its reach can be scaled without limit. An integrated belt hoist also enables reliable operation in warehouses with very low ceiling heights.

Column Lift System – PROPAL S

The PROPAL S220 is based on a free-standing column structure with a flexibly positioned gripping tool. Packaged goods can be moved along up to four axes, enabling a wide range of palletizing, depalletizing, and other handling tasks. This makes it the perfect solution for processes requiring maximum versatility.

Labeling System

Product

Labeling System – PROLABEL

Labeling with PROLABEL C

The PROLABEL C130 is a fully automated, space-saving label applicator for pallets and packages. The number and position of labels can be freely defined and flexibly adjusted. Labeling is possible on up to three sides of the load unit. The system integrates seamlessly into existing production lines. Thanks to the use of a cobot, collaborative applications are possible – eliminating the need for bulky protective enclosures and ensuring maximum flexibility in the production environment.

Labeling with PROLABEL R

The PROLABEL R150 is a fully automated, space-saving label applicator for pallets and packages. The number and position of labels can be freely defined and flexibly adjusted. With its overhead robotic placement, labeling can be carried out on up to five sides. Like all systems in the PROLABEL series, the R150 is designed for seamless integration into existing production lines, ensuring precise and reliable marking.

Cobots

Product

Moving, Gripping, and Lifting with Cobots

Kassow kr810

load capacity: 10KG

range: 850MM

Kassow kr1018

load capacity: 18KG

range: 1000MM

kassow kr1205

load capacity: 5KG

range: 1200MM

kassow kr1410

load capacity: 10KG

range: 1400MM

kassow kr1805

load capacity: 5KG

range: 1800MM

Handle Application

Product

Handle Application with PROGRIP

Manual Handle Application – PROGRIP

The fast and straightforward way to apply carrying handles manually. For small production volumes, the PROGRIP M & A models are the optimal solution. They are quick, simple to operate, and highly reliable.

Automatic Handle Application – PROGRIP

The automated handle applicators of the PROGRIP series are designed especially for high-performance environments, processing up to 420 packs per minute.

Banding