Driverless Transport Systems

Driverless Transport Systems

Driverless Transport Systems – Automated Material Logistics

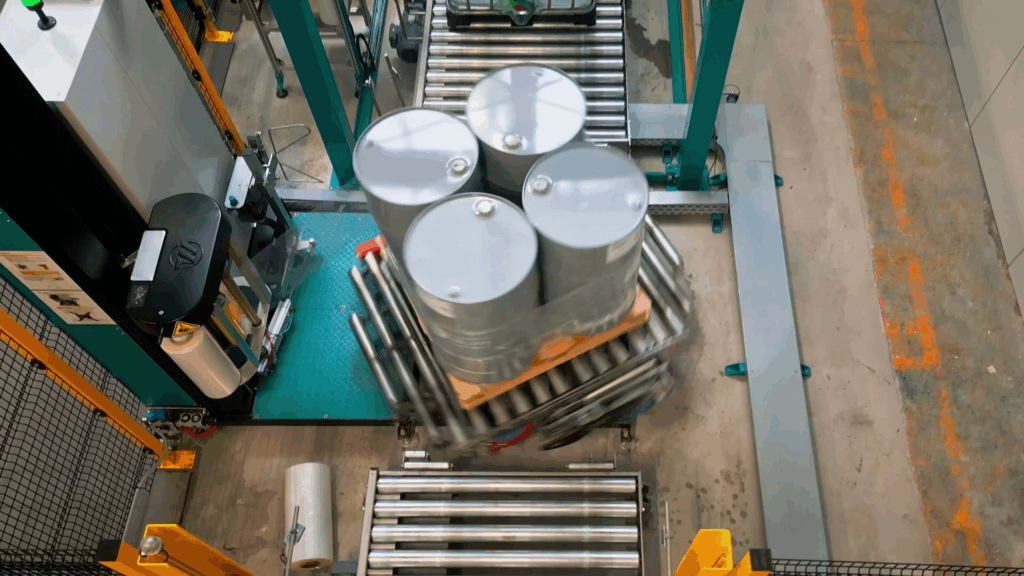

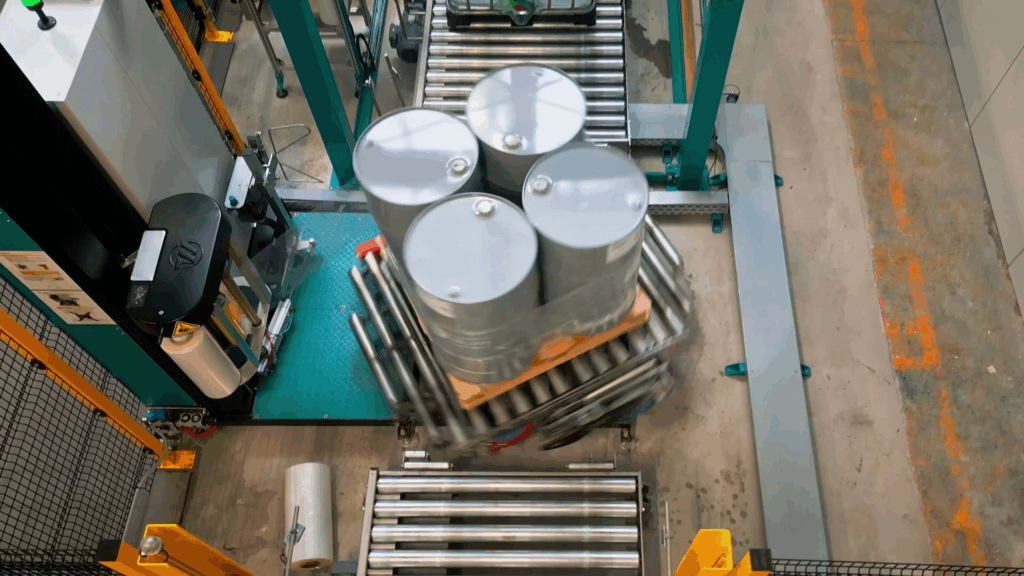

AGV systems (Automated Guided Vehicles) are self-driving transport units with integrated conveyors that move materials efficiently within production and warehouse environments.

Following pre-defined floor paths, AGVs automatically stop when obstacles are detected, ensuring both safety and continuous operation. These driverless transport systems integrate seamlessly into existing production lines and significantly improve the flexibility, efficiency, and reliability of your internal material flow.

Technical Features & Functionality

- Self-driving transport vehicles with integrated conveyor technology

- Line-guided navigation via floor markings or embedded tracks

- Automatic stop function for obstacle detection and collision avoidance

- Various conveyor options depending on transported goods and load types

- Models for medium (1,500 kg) and heavy-duty (3,000 kg) applications

Customization & System Integration

Each AGV can be custom-configured to meet specific customer requirements – from conveyor type and load capacity to transport performance.

The vehicles can be effortlessly integrated into existing production layouts and material handling systems. Interfaces to higher-level control systems allow for coordination of multiple vehicles and full integration into automated production and logistics processes, enabling efficient, connected, and safe intralogistics operations.

Product Variants

- PROCON AGV 1500

Load capacity: 1,500 kg

Navigation: Fixed track guidance (surface or in-floor)

Automatic obstacle detection and stop function

Configurable with various conveyor systems

- PROCON AGV 3000

Load capacity: 3,000 kg, capable of transporting up to two pallets simultaneously

Navigation: Fixed track guidance (surface or in-floor)

Automatic obstacle detection and stop function

Configurable with various conveyor systems